close

Choose Your Site

Global

Social Media

What is an Optical Fiber RecoaterHave you ever wondered how optical fibers maintain their strength and clarity? An Optical Fiber Recoater plays a crucial role in this process.

How much does a fusion splice cost?Are you curious about the costs involved in fusion splicing? This essential process plays a vital role in fiber optic networks.In this article, we will break down the costs associated with fusion splicing.

What is the best fiber optic splicing machine?Are you struggling to find the best fiber optic splicing machine?Fusion splicers are essential tools in modern communication networks. Choosing the right one can significantly impact signal quality and overall performance.

Which tool is used for stripping the fiber cable?Fiber optic cables are crucial for high-speed communication today. Stripping these cables correctly is essential for effective installation and maintenance.

What does a fibre cleaver do?Have you ever wondered how fibre optic connections are made? Fibre cleavers play a crucial role in this technology.In this article, we will explore what a fibre cleaver does and its importance in the fusion splicing process.

Have you ever wondered how fiber networks stay lightning fast? Fusion splicing holds the secret — it’s the key to strong, seamless fiber links.

Ever wondered how fiber networks stay strong? Fusion Splicer makes seamless connections possible. It reduces signal loss and strengthens joints.

Ever wondered how fiber networks stay fast? Reliable connections need precision tools. A Fusion Splicer joins fibers with minimal signal loss.

Fiber optic networks are the backbone of modern communication. Reliable connections are vital for fast,uninterrupted data. Fusion Splicer joins fibers with minimal signal loss.

Fiber networks need precise testing. Can a Fusion Splicer perform OTDR? This article explains its limits and uses. You will learn when to use each tool, covering splicer capabilities and best practices for accurate fiber measurements.

| Availability: | |

|---|---|

| Quantity: | |

X-900

SHINHO

Product Description

、

6 Motor(Imported)Core to Core Alignment

◆ High precision splicer(imported motors)

◆ Core to core alignment system with adjustable focus of fiber core

◆ Full automatical propulsion splicing

◆ Calibrate the Arc in a realtime

◆ Fiber type identification automatic supported

◆ 3 in 1 fiber holders,adapt to various work needs

◆ 4 core CPU with a lower power cost

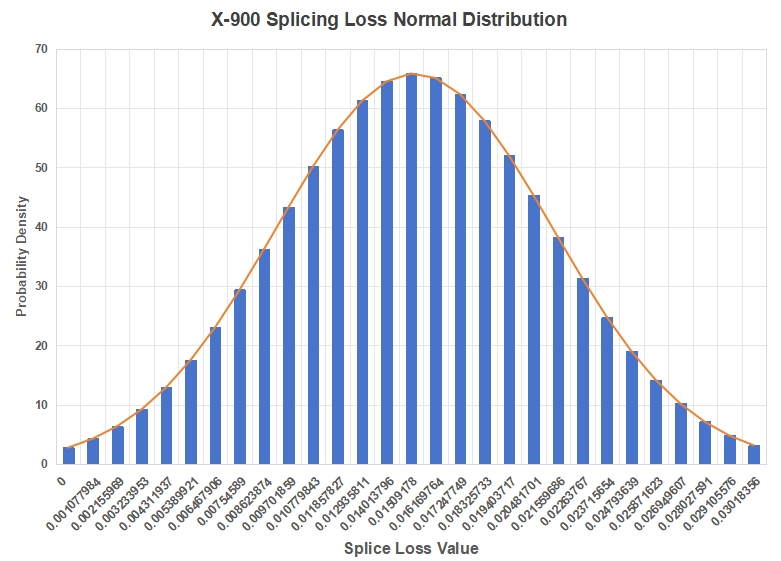

Actual Measured 200 Core Probability Density Chart

MORE INFO

Precise structural design Core to core alignment

Inductive automatic heater

Fast heating

Anti-shock, dust-proof and water-proof, 5" touch LCD

Multi-Language Sites

Operating Condition

SPECIFICATIONS

Alignment Method | 6 motors core to core alignment |

Applicable Fiber | G651/G652/G653/G654/G655/G657 etc. |

Cladding Diameter | 80~150μm |

Coating Diameter | 160~3000μm |

Cleaved Length | 10~16mm (coating diameter<250μm), 16mm (coating diameter:250~1000μm) |

Typical Splice Loss | G651: 0.01dB; G652: 0.02dB; G653: 0.04dB; G654: 0.04dB; G655: 0.04dB; G657: 0.02dB |

Return Loss | >60dB |

Splicing Program | 40 modes |

Operation Mode | Manual/ Auto |

Auto-Heating | 100 modes, auto-heating supported |

Splicing Time | 6~12 seconds; fast splicing time 6 seconds |

Heating Time | 18~26 seconds for 40mm and 60mm shrinkable sleeves |

Fiber Magnification | 400X (X or Y view), 200X (X and Y view) |

Viewing Display | Dual high sensitivity camera, 5" HD color LCD touch screen |

Data Storage | 10000 groups data records, 100 groups images |

Loss Evaluation | Available |

Tension Test | 1.8~2.2N |

Interface | GUI menu interface, easy for operation |

Battery Capacity | Detachable 5200mAh Li-battery, typical 300 cycles splicing and heating |

Power Supply | Adapter, input: AC100~240V(50/60Hz), output: DC11~13.5V |

Electrode Life | 5000 ARC discharges, easy to replace |

Terminal | USB 2.0 port, for software upgrading and records exporting |

Operating Condition | Altitude: 0~5000m; Humidity: 0~95%; Temperature: -10°C~+50°C; Max wind: 15m/s |

Dimension/Weight | 155mm(L) × 144mm(W) × 155mm(H) (including rubber bumper)/2.37kg(with battery) |

PACKAGE

Fiber Cleaver

Spare Electrodes

User Manual

Cleaning Brush

Carrying Case

CUSTOMER PRAISE

FAQ

1. Why Choose SHINHO?

----SHINHO is founded in 2012 by a team of engineers with 20 year's experience in this industry. We focus on the manufacturing of fusion splicer and the quality since beginning.The software and hardware are all designed and implemented at our own plant. We have professional production line and staff who are making nice quality in short time.

2. What Certificate you have?

-----CE,Rohs, and ISO.

3. What is the warranty?

----- 3 Years from the date from you received the splicer.

4.Is there any discount for the splicer?

-----Yes, the price depends on the quantity, please contact us for details.

5. What should I do if I have a problem with the machine?

-----When you have problem, please share video or photo to us, we will guide you how to solve the problem. Usually most problem could be solved via remote guidance or software upgrading. We are experienced in this.

6. How to be your distributor?

-----We welcome customers to be our distributor. We will give you full support. Contact us if you are interested.